As the interface between the charging unit and the end device, spring-contact battery connectors play a crucial role. In this case, the focus is not only on the spring contacts’ technical specifications – such as the minimum number of mating cycles, the contact resistance or the current-carrying capacity – but also on the special shape of the connector housing, which is designed to support uncomplicated, fast, simple, and reliable connections that ensure stable contact.

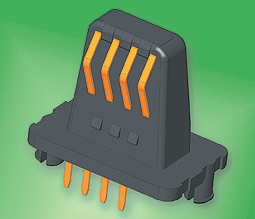

One good example of SUYIN’s flexible production capabilities is its 060069MS model for use in charging units or base stations. This 4-position vertical spring-contact connector is prepared for through-hole mounting. Its contact mounting plate is tilted slightly from the vertical axis to the inside at an angle of 8° in order to make it particularly convenient to connect the device to be charged, without having to sacrifice connection reliability. For the same reason, the charging connector’s sides are also slanted inward from the vertical axis at a 5° angle. Inside the housing itself, specially formed plastic ribs serve as a locking mechanism in order to ensure high contact reliability, even when the connector is subjected to vibrations. When used in base stations, the connector can also serve as a data connector. Two side-mounted guide pins that are offset at an angle provide additional anchoring on the carrier board. The copper-alloy contact springs, which are arranged at a pitch of 1.5 mm and are plated with gold over nickel, are configured for 12VDC / 2A per pin, and the connectors are specified for at least 5,000 mating cycles.

Beginning at order quantities of 100 k, SUYIN is able to make such application-specific adaptations quickly and inexpensively in close collaboration with the customer.

SUYIN Corporation

www.suyin-europe.com