As Industry 4.0 is implemented, besides Gigabit lines, wireless technology will increasingly be taking its place on the industrial scene.

As Industry 4.0 is implemented, besides Gigabit lines, wireless technology will increasingly be taking its place on the industrial scene.

The question is no longer if, but how and when will wireless technology take hold. Here are the most important answers.

Standards for the wireless transmission of measurement and control data have developed a great deal, which is causing even the most recent critics to rethink their stance of “our system must operate − wireless is not secure enough”. But deciding which standard is the most appropriate depends on the application.

Field level I

Close to the work piece, but must be flexible, self-sufficient, and maintenance-free

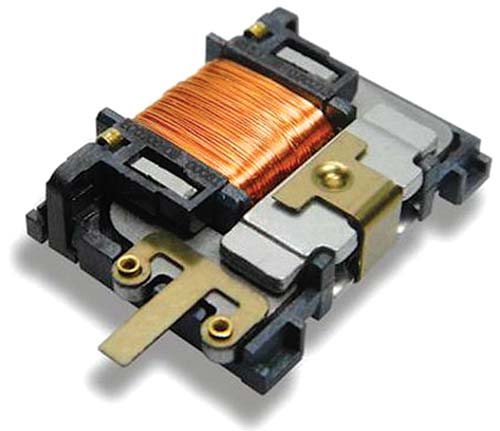

On newer production lines, one is struck by the first sensors and actuators that manage without cables and sliding contacts. They are flexible to install and they enable totally new motion sequences in production processes. Previously, a flat battery, which causes a production stoppage, has been the most frequently cited reason for not installing such solutions. But now, self-powered sensors and actuators are standing the test. With their energy-harvesting modules they are able to convert ambient light energy or heat differences into sufficient electrical power to be able reliably to send data packets over short-range wireless connections, up to a few hundred meters. A local energy storage unit ensures failure-free functionality for weeks, if at any time it is not possible to harvest sufficient energy from the environment. Besides the Sub Ghz protocol EnOcean, Bluetooth 5 and ZigBee 3.0 on the 2.4 Ghz band are also available to network the sensors and actuators.

The ZigBee Alliance appears to have learned from the mistakes of the past. So version 3.0 is proving popular not just in the Amazon Echo, Philips Hue, Ikea Trådfri and Osram Lightfy, but also – due to its specifications − in the industry sector too. A compatible EnOcean module combination takes care of the energy-harvesting with ZigBee. The wireless unit − like the wireless stack − is based on a semiconductor supplied by Nordic Semiconductor.

For straightforward P2P connections or for interaction with a smart phone, tablet or laptop, Bluetooth can likewise be used and is fully self-powered.

If a wider range is required or if, due to the frequency plan, it is not possible to use the 2.4 Ghz band on the site, the EnOcean protocol from the EnOcean Alliance offers a proven alternative. This too deploys EnOcean modules for energy conversion and wireless communication. As distributor, Rutronik is working together with EnOcean GmbH and the EnOcean Alliance, as well as with Nordic Semiconductor. It means that developers industry-wide can find a solution even for software-specific adaptations and for more complex problems.

Field level II

Always on receive − cross-linking inside the factory building

In larger and more complex networks, where connections make use of sensors or actuators to the gateway, hub or to an Edge computer, what looks like the perfect solution − because it is maintenance-free and self-sufficient − soon reaches its limits. Particularly with non-time-synchronized mesh topologies each wireless node must be permanently on receive in order to receive incoming data packets and ensure that they are processed immediately. This requires a supply of permanent and more intense energy. In the case of stationary wireless nodes, wired power sources are available, while for “floating” wireless nodes Airfuel charging technology is the mobile alternative that allows a lot more movement than Qi charging technology. The best compromise to meet different requirements is generally the traditional battery.

Many wireless standards such as Bluetooth Mesh, WiFi Mesh and ANT Blaze, have a history based on a star topology and for a few years have also been supplying mesh topologies. ZigBee, Threat and some others were designed from the start for mesh networking communication. While WiFi Mesh manages with practically zero power supply, all the other mesh systems mentioned can operate for months on one battery charge.

As against the home sector, where ZigBee controls the LED light sources, it is apparent that unrouted Bluetooth Mesh sets the standard for industrial lighting systems in warehouses and production halls, open plan offices and hallways. Unlike the conventional method of specifically routing data packets, with these, the data flow ensures particularly rapid reaction and throughput times. Despite this, smart phones and similar can be integrated into the network, providing another huge advantage over other wireless standards which have to find their way to the IT equipment via a router.

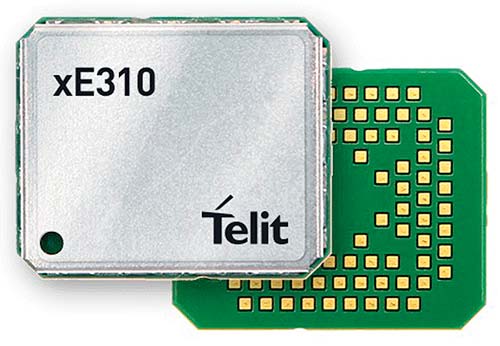

Bluetooth Mesh is an intermediate layer which can in theory be placed on any Bluetooth 4.0 hardware. However, due to the latest pricing system set by the Bluetooth Special Interest Group, when designing a new system, it is a good idea to use more up-to-date Bluetooth 5 or 5.1 hardware. Rutronik supplies semiconductors with the relevant stacks from STMicroelectronics, Redpine Signals, Nordic Semiconductor and Toshiba. If you prefer a solution with integral high frequency circuitry and certification, you can choose Bluetooth Mesh modules from Insight SiP, Garmin, Panasonic, Murata, Telit, Fujitsu, Minew and Redpine Signal.

Field level III

Field level III

Outside visual range, but closely connected

At transshipment points such as logistics centers, railway stations and ports, long-range wireless is the method of choice. Of the technologies using public and license-free ISM bands, LoRa has become established in most central European countries. France and the Netherlands have mainly settled on Sigfox because of its good network expansion.

However, 2019 saw a changing trend: the Cat M1 and Cat NB1 4G standards for narrowband IoT have undergone strong growth, depending on the region and the application. The initial test phases have already moved into series production. While the LTE-M is available for tracking applications with cell changing, the LTE NB1 uses even less energy.

However, in many countries the network is undergoing expansion and low power mobile wireless technology is being deployed. German mobile wireless suppliers are clearly concentrating primarily on the metering market. Since an installed electricity, gas or water meter does not move, there is no need to change mobile wireless cells during a connection. Providers in other countries prefer to opt for tracking applications for moving objects and have focused on expanding category M1. Most mobile wireless module manufacturers support both networks; Rutronik has solutions from Telit, Nordic Semiconductor, Murata, Telic, Advantech and, soon, from other franchise partners.

However, in many countries the network is undergoing expansion and low power mobile wireless technology is being deployed. German mobile wireless suppliers are clearly concentrating primarily on the metering market. Since an installed electricity, gas or water meter does not move, there is no need to change mobile wireless cells during a connection. Providers in other countries prefer to opt for tracking applications for moving objects and have focused on expanding category M1. Most mobile wireless module manufacturers support both networks; Rutronik has solutions from Telit, Nordic Semiconductor, Murata, Telic, Advantech and, soon, from other franchise partners.

Like 2G, 3G and conventional 4G modules, LTE M1 transceivers are also often combined with GNSS (Global Navigation Satellite System) into a single housing because they are intended to track and monitor the position and motion of containers, vehicles, high-end goods, people and animals. The position has to be defined and transmitted via the mobile wireless network. A few years ago, GPS was a navigation system that was almost without competition. But GNSS alternatives came on line in the form of the Russian Glonass and the Chinese Beidou systems, although they are not quite up to the standard of the American system. In 2019 the European Galileo made its breakthrough; it has been operating successfully in millions of smart phones for some time now. In mid-2019 the decision was made to make greater tracking accuracy available free of charge, so that Galileo is now ahead of the GPS system with regard to free use of layer 1 data. In addition, Galileo is the only system to provide an authentication function. This ensures that the received signals actually come from Galileo and not from a counterfeit transmitting station. And Galileo is the only civilian system operating within a democratic country. Nevertheless, almost all users would be best advised to install as many systems in parallel as possible. Because the more satellites that are used, the faster, more energy-efficient, and more accurate can most modern multi-GNNS receivers work. However, we should be ready for future changes and be able to react if one of the systems should fail. The NB1 or M1 modem available in the module can be used to change the firmware settings.

For applications using GNSS with LoRa, Sigfox, WiFi or Bluetooth, it is necessary to ensure a corresponding option to access the GNSS unit’s operating mode in the host controller. Usually it is sufficient to create an NMEA control command, to tell the receiver which systems it should use, and which it should ignore. This remote functionality must always be implemented manually and in the worst case it could prove disastrous for the application but could also be a life or business saver.

Process level

Welcome to 6th generation WiFi

At processing level all the data from the individual workstations are collected together. Often the data collected at the field level sensor has not been prepared at all. To obtain information from it, a minimum of a preliminary processing of the data takes place. For many applications it is advantageous to be able to use this to compare several field data received in parallel. Elaborate pattern matching algorithms can be set up that not only compare against both static patterns but which constantly need to adjust their reference as well. To cope with this and with similar computing-intensive tasks, heavier-duty x86-based systems are used as a general rule.

Here the trend is towards interconnection and in the direction from system level to wireless technologies. However, the 6th WiFi generation is not just faster than the earlier ones, but is also distinctive for better connection management for subscribers, which scores particularly well in professional installation scenarios. Another plus point is its improved frequency assignment with the soon-to-be-introduced 5G network.

With Intel as its technology partner, Rutronik has been able to provide its customers with market-ready WiFi 6 solutions from the start. m.2 PC cards in particular were in great demand for industrial PCs, Panel Pcs and NUCs

System level

System level

It is down to the location

The choice of technology at system level is heavily dependent on the complexity and the local circumstances, such as the extent of the factory site or the operational frequency plan. For smaller dynamic operations, WiFi 6 can be a solution, while for larger companies with very static installations, a cabled solution would − still − be a solution. Yet as soon as 5G is available and affordable, it will be necessary to rethink these installations too.

Operative level

Here, the earlier generation is still an option

When communicating between different plants, the information is so heavily condensed beforehand that conventional LTE is fully sufficient to cope with the data throughput and latency periods − even in major international corporations. Those wishing to ensure their cabled on-site internet connections can already transmit important key operational data by mobile wireless via an LTE router.

Where users opt for field level, where it is a matter of individual sensor data, usually mostly for the lower LTE categories, it is possible at operational level to opt for LTE category 6 or higher. Power consumption and the price of the modem are negligent because the computers always operate from the mains, and only a very few LTE modems or LTE routers are used. Telit, Telic, and Advantech supply solutions such as PC cards, external modems and routers. For example, an individual total solution might combine them with an Intel or Asus server, configured with an LTE modem from Telit and a WiFi 6 card from Intel.

More wireless trends in automation

Following its success in end-customer smart phones, a further technology is also making headway in industrial environments. 13.56 Mhz technology enables secure exchanges between active reader and passive transponder as well as between two active readers. Since it is compatible with almost all modern tablets and smart phones, economical standard hardware is available; there is often no need to deploy more expensive special devices such as an RFID Gun. Besides the cost of the hardware, this provides software programming benefits too.

Those wishing to use RFID for longer distances or to scan several transponders at once still either need to use another frequency or look around on active systems. In this case the transponders are not supplied from the reader’s electromagnetic field, communicating via load back coupling, but they have their own power supply (usually a battery or solar) and communication in 2.4 Ghz band based on Bluetooth or a similar proprietary wireless protocol.

Where neither fixed cabling nor energy harvesting are options, and even economical wireless connections such as Bluetooth Low Energy deplete the batteries too quickly, increasing numbers of industrial applications are choosing the ANT protocol. For example, the first Time-of-Flight sensors will soon be available for high accuracy distance mapping, which require very little power.

In addition, ANT is available ex works in most Android smart phones, and with multiprotocol SoC solutions can transmit data traffic in Bluetooth networks without incurring further hardware costs.

“Innovation in Automation”

Using the latest wireless technology

The “Innovation in Automation” series of online seminars provides informative videos on demand from the leading manufacturers of electronic components for Industry 4.0. They demonstrate solutions for the industrial plants of the future; sub-themes are artificial intelligence, robotics and networks.

The seminars also include a presentation by Telit as supplier of mobile wireless, M2M sim solutions, IoT device management and short-range wireless, and by Intel, producer of WiFi 6 solutions. Simply register at https://www.rutronik.com/seminars/ innovation-in-automation-2019/.

Author: Bernd Hantsche, Director Product Marketing Embedded & Wireless

Rutronik | https://www.rutronik.com

![]()