Semiconductors are without a doubt one of the most significant developments in mankind’s history. Without them, the whole computerization would not have been possible. Also, the world as we encounter it today would be an alternate one.

Semiconductors are without a doubt one of the most significant developments in mankind’s history. Without them, the whole computerization would not have been possible. Also, the world as we encounter it today would be an alternate one.

With the physical properties of silicon, the most widely used semiconductor, pushed as far as possible, the chase for new material starts. However, carbon may be the perfect possibility for use in this purpose.

Silicon

The first Semiconductor properties were found in the mid-nineteenth century by Thomas Johann Seebeck who watched a diminishing resistance value of silver-sulfide with expanding material temperature. Which is one of the key attributes of a semiconductor.

Semiconductors are defined as a material with electrical conductivity between a conductor (for example copper) and an insulator (for example glass). The properties of the material can be modified by a procedure called „doping”. By polluting the wafer material with other substances, electrical, optical and auxiliary qualities of the result can be adjusted to specific needs.

Semiconductors are defined as a material with electrical conductivity between a conductor (for example copper) and an insulator (for example glass). The properties of the material can be modified by a procedure called „doping”. By polluting the wafer material with other substances, electrical, optical and auxiliary qualities of the result can be adjusted to specific needs.

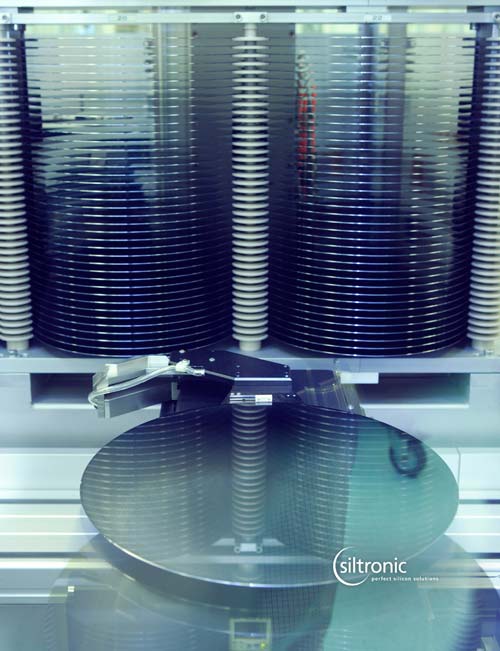

However, undesired pollutions represent a major danger to debasing and crushing whole productions. Silicon semiconductors are developed from pure quartz sand. In a procedure called the Czochralski method, this sand is molten into a solid block of silicon. The resulting silicon ingot gets cut, ground and etched into round wafers of extreme levelness. The unevenness of these wafers is limited to sizes littler than 1 nanometer. The standard width of wafers is 300mm, with a thickness of 775 micrometers. These wafers serve as a substrate material for electronic components.

The scaling down of integrated circuits and electronic parts has arrived at its cutoff points with silicon. Without the ability to minimize ICs further, silicon can’t continue delivering the results it has up until this point. Meeting this undertaking may require rethinking how we produce devices, or even whether we need a substitute for silicon itself.

Carbon

Carbon is a basic element on earth. It is available in all living tissue. And also in a wide range of physical structures. The properties that make carbon so fascinating for the electronics business, is its exceptional electron design. Because of four electrons accessible to shape compound bonds, it can form complex particles. Under ordinary conditions, carbon is a very unreactive element.

Graphite

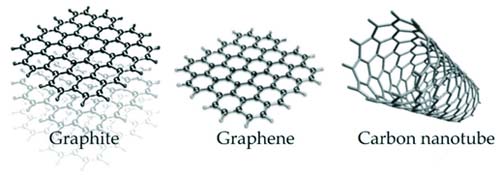

For use in the electronics industry, Carbon is only a nonexclusive term. More important than the raw resource are its allotropes. The first being Graphite. Which is an exceptionally pure type of Carbon. The atomic structure of Graphite is a hexagonal grid that is key for its qualities. Graphite is a decent conveyor of power and heat, that is the reason it is very much utilized in the creation of electrodes. Alongside its electrical properties, Graphite is an amazing lubricant, which makes it a distinct advantage in the creation of self-greasing bearings.

Graphene

A nearby auxiliary connection to Graphite keeps up the adjusted carbon component Graphene. Every carbon particle connects at a 120° angle, which prompts a similar honeycomb or hexagonal structure as in Graphite. However, Graphite comprises of numerous layers, which gives it a 3D structure. Whereas Graphene is available in 2D. This „flat” example of Graphene is a key factor for the utilization of carbon in electronics. Because of this circumstance, it can be folded into a cylindrical structure, which prompts amazing qualities. Likewise, Graphene is fit for being doped with different substances. For instance, the acquaintance of Ammonia leads with expanded reliability in RAM gadgets. Graphene capacitors are electronic parts, that are available in large scale manufacturing. The points of interest over ordinary supercaps are high currents, high capacity, lower leakage current, low electron paramagnetic resonance, and selfmending attributes.

The carbon nanotube (CNT)

The carbon nanotube (CNT)

A sheet of Graphene collapsed into a cylinder is known as a carbon nanotube (CNT). A nanotube is characterized as a cylindrical geometrical structure with a diameter under 100 nanometers. CNTs can be created as a solitary cylinder, or various cylinders stacked into one another, to additionally expand quality and effectiveness. Efficiency and robustness are the center abilities of CNTs. There is no material more grounded and stiffer when it comes to tensile strength.

Carbon nanotubes can adopt either metallic or semiconductoral characteristics, which makes them exceptionally flexible. In addition to that, CNTs have amazing electrical conductivity.

Practical use of Carbon nanotubes

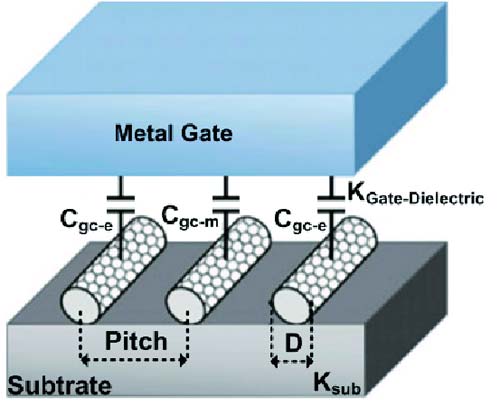

Regardless of being available for a few years as of now, CNTs still aren’t available on a commercial scale. Manufacturing costs are still higher than with silicon semiconductors. One potential application is the Carbon nanotube field-effect transistor (CNFET). It is based on the traditional metal-oxide-semiconductor field-effect transistor (MOSFET) structure, yet utilizes CNTs in the plan. CNFETs have certain characteristics to them, that outperform regular MOSFETs. The higher electron portability accounts for a gate capacitance of about twice the value of a MOSFET. Additionally, CNFETs have a higher current density and transconductance. A CNFET is less likely to self-heat to a level that destroys the component. On the other hand, CNFETs are costly to produce, and their lifetime and dependability are still not on the same level as silicon-based FETs. To turn CNT based components into a widely available product, new manufacturing or implementation techniques need to be found. At current state, carbon

Regardless of being available for a few years as of now, CNTs still aren’t available on a commercial scale. Manufacturing costs are still higher than with silicon semiconductors. One potential application is the Carbon nanotube field-effect transistor (CNFET). It is based on the traditional metal-oxide-semiconductor field-effect transistor (MOSFET) structure, yet utilizes CNTs in the plan. CNFETs have certain characteristics to them, that outperform regular MOSFETs. The higher electron portability accounts for a gate capacitance of about twice the value of a MOSFET. Additionally, CNFETs have a higher current density and transconductance. A CNFET is less likely to self-heat to a level that destroys the component. On the other hand, CNFETs are costly to produce, and their lifetime and dependability are still not on the same level as silicon-based FETs. To turn CNT based components into a widely available product, new manufacturing or implementation techniques need to be found. At current state, carbon

nanotubes that can be furtherly processed require a purity of 99.999999%. Which only accounts for a small percentage of manufactured badges.

To show the abilities this innovation offers, Analog Devices and the Massachusetts Institute of Technology have built a 16-Bit microcontroller, based on the RISC-V structure. The RV16X-Nano named controller is made out of 14,000 reciprocal FETs and is capable of running the total RISCV order set.

What’s surprising about this microcontroller, are the creation methods utilized. The CNFETs are arranged in a manner that requires a lower CNT purity of 99,99x%, which current assembling procedures can mass produce. CPUs and microcontrollers dependent on CNTs are expected to be approximately ten times more energy-efficient than current processors, while also running a lot faster.

Recent achievements provide an example, of just how much potential lays inside the utilization of carbon in the electronics industry. But at the current state, it’s not possible to pinpoint if and when exactly, carbon-based electronic components are going to be the new standard parts.

Make sure to stay up to date on everything that’s happening in the electronics industry!

![]() Sina Hoefer studied Economics and English in Newcastle, UK and Landau, Germany. After graduation, she began her career as an assistant buyer at one of the biggest German hardware store chains. She is very passionate about technology and especially electronics. In her spare time she reads and writes about emerging topics in the electronics industry.

Sina Hoefer studied Economics and English in Newcastle, UK and Landau, Germany. After graduation, she began her career as an assistant buyer at one of the biggest German hardware store chains. She is very passionate about technology and especially electronics. In her spare time she reads and writes about emerging topics in the electronics industry.