Trelleborg Sealing Solutions launches Turcon® MC1 and Turcon® MC2 materials, the only polytetrafluoroethylene (PTFE) based electrically conductive materials suited for use in spring and elastomer-energized seals. Engineered for dynamic applications, seals and bearings from the materials will provide reliable electric connection between moving parts.

Trelleborg Sealing Solutions launches Turcon® MC1 and Turcon® MC2 materials, the only polytetrafluoroethylene (PTFE) based electrically conductive materials suited for use in spring and elastomer-energized seals. Engineered for dynamic applications, seals and bearings from the materials will provide reliable electric connection between moving parts.

Konrad Saur, Vice President Innovation & Technology for Trelleborg Sealing Solutions, says: “Turcon® MC1 and Turcon® MC2 are unique and are specifically developed for use in spring and elastomer-energized seals, as well as bearings, in response to a strong market demand to support electrification of drives, eMobility, sensing and IoT solutions.”

Soeren Roepstorff, Development Manager at Trelleborg’s manufacturing facility in Helsingør, Denmark, where the new compounds were developed, says: “Conductive elastomers are available, but these are primarily only for static applications, while the conductive, injection-moldable plastic materials that exist have low flexibility and are less suited for sealing purposes and for installation in closed grooves. “Turcon® MC1 and Turcon® MC2 meet our customers’ demands for conductive plastic sealing materials that will work effectively and reliably as seals and bearings in dynamic applications. With them, designers can take advantage of using a range of advanced PTFE-based sealing geometries and all the benefits that they offer in applications that require electrical conductivity through a hydraulic system or electric motor, for instance.”

Virgin PTFE is an excellent insulator with resistivity around 2×10+17 Ohm-cm. For PTFE composites to be able to conduct electricity, conductive fillers must be added, and these need to interconnect within the PTFE matrix. Historically, the only conductive PTFE-based materials were compounds with carbon filling above a “threshold value”.

The fact that electrical conductivity was achieved in these original carbon filled PTFE-based materials was accidental and electrical resistance was not the primary engineering requirement. Turcon® MC1 and Turcon® MC2 differ though, in that they have been specifically developed for electrical conductivity in dynamic sealing applications and therefore sealing performance is optimized in these situations.

Electrically conductive sealing materials have some important applications:

- In aircraft, a worst-case scenario is that a plane is hit by lightning but less traumatic is the static buildup that occurs as a plane flies through the air. Electrically conductive seals in the landing gear, for instance, will ensure that electricity or static is safely dissipated.

- Electric charge transfer through the gap between two components can cause sparks or stray current in machinery and systems, for example in electric motors. This can result in hardware pitting and carbonization of lubricant or grease. Use of an electrically conductive seal or bearing grounds the system by creating a clear path between two components, avoiding corrosion issues.

- Sometimes intentionally a signal needs to be sent to or from a sensor in a system. This signal transfer can be achieved by utilizing electrically conductive seals or bearings that will create a clear path for the signal, enabling system manufacturers to develop more complex systems incorporating aspects of artificial intelligence without adding electrical circuitry.

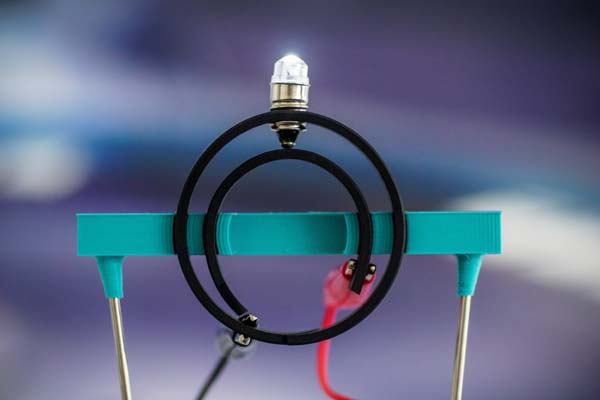

To prove the electrical conductivity of Turcon® MC1 and Turcon® MC2, the compounds underwent significant testing in the Trelleborg’s in-house labs, including in a specialized test rig that simulated real life conditions. Results showed that Turcon® MC1 and Turcon® MC2 had a dry contact resistance that was negligible (highly conductive) even with low contact pressure and when running in oil, resistance was also low and thereby, conductivity was high.

Turcon® MC1 is a medium-filled material for dynamic applications requiring medium to high conductivity, while Turcon® MC2 is a high-filled material for dynamic applications requiring high conductivity.