What are solid state relays?

What are solid state relays?

In electrical terms, a relay is a relatively simple switching device that’s used to automatically close or open a set of contacts between two circuits. This process is triggered by an electrical input or control signal of some kind, in response to which the relay switch usually moves from an ‘off’ to an ‘on’ position.In a standard relay, the process is electromechanical (hence these relays being referred to by the acronym EMRs). In other words, an electrical control signal triggers a mechanical response in the relay. The standard mechanical relay switch is therefore composed of key moving parts, and it’s these parts that physically change position in order to open/close the contacts and complete or break the circuit as required.

By contrast, a solid state relay has no mechanical or moving parts. As electrical components, SSRs are widely used to perform much the same on/off, open/close functions as standard relays, but a solid-state switch does so entirely without any physical movement within the relay itself.

The term ‘solid state relay’ is ageneric one, and can, in fact, refer to all manner of different relay components and configurations used to achieve the basic on/off switching function.

Many of these configurations will be designed around specific industries or applications. Solid state relays made for automotive use, for example, tend to be optimized for plug-and-play installation methods and resilience against harsher environmental conditions (anti-vibration, over-voltage protection, polarity reversal and short circuit protection) than you’d typically encounter in, say, industrial or production applications.

What are solid state relays used for?

What are solid state relays used for?

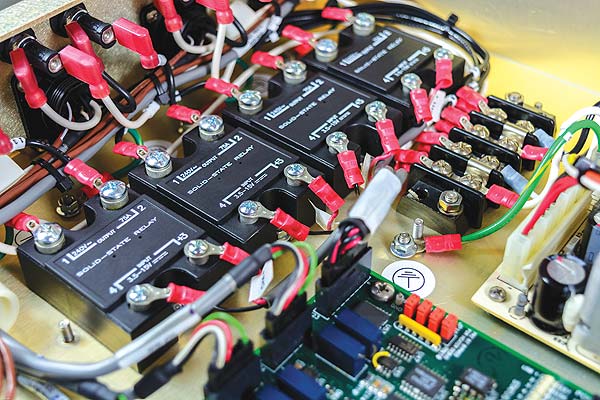

Solid state relays are widely used in a highly diverse range of applications, sectors and industries, includingindustrial controls, motor control, robotics, medical equipment and patient/equipment isolation, instrumentation, meters, home appliances.

How do solid state relays work?

As noted above, the key characteristic of a solid-state relay is that it requires no moving parts to perform the task of opening or closing contacts on a circuit.

Unlike a mechanical relay, there’s no positional change of any component within the solid state relay when it switches between on/off, open/closed states. Instead, a solid-state relay works by converting the incoming electrical control signal to an optical one, often output via an infrared LED or similar (note, however, that the term ‘solid state relay’ is a generic one, and covers a variety of configurations).

This optical signal is then fired across a small gap of (permanently) open space within the module – known as an opto-isolator – to where it’s received by a photosensitive transistor, which in turn converts and sends on the signal to further electrical components. This completes the circuit and ultimately triggers the desired action, all without any contacts in the solid-state relay ever coming into direct physical contact with one another.

Solid state relay mount types

In addition to there being numerous different types of solid-state relay switches sold in worldwide markets, there is also a very wide range of mounting solutions available for physically installing them to circuits or housing them as part of a wider electrical system. Some of the more common mounting solutions for solid state relays: PCB mounts, DIN rail mounts, panel and chassis mounts, heatsink mounts, plug-in mounts.

|

|

|

|

|

|

Solid state relay comparisons

The most common comparisons made between solid state relays vs mechanical ones are broadly based on two key factors: speed of operation, and overall longevity.

As we’ll see, solid state versions tend to outperform mechanical relays on both counts, because the lack of moving parts in a SSR means it can work faster and for longer without needing replacement than an equivalent mechanical version.

Despite this general rule of thumb, though, there may still be specific applications and environments in which mechanical relay switches remain a more suitable option, and are actually preferable to solid state switches in day-to-day use.

Solid state relays vs mechanical relays

Because the SSR is basically using light and/or sensors to transfer the signal, rather than physical movement, switching between on/off states can be performed orders of magnitude faster than in EMR equivalents.

This means that SSRs boast a range of abilities and characteristics that may be of potential value in many specific usage applications and industries. Application-specific advantages of solid-state relay switches might include:

• Very little wear over time thus increased longevity on paper (Electromechanical relays with moving parts will eventually need replacing)

• Near-silent operation

• Ability to perform extremely fast/high-frequency switching

• Typically, far lower power consumption than EMRs

• No potential for sparking caused by rapid movement of components (This is important in some chemically volatile or potentially explosive environments)

• Reduced risk of contact failure due to physical defects or inconsistencies

• No risk of ‘bouncing’ contacts (accidental multiple contacts made, to due inaccuracy or inadequate cushioning of movement)

• Solid state relays themselves can be manufactured in far smaller and more compact form factors than mechanical versions

To complete the above actions reliably, smoothly and quickly without performing any actual mechanical action, SSRs instead rely on a number of other crucial components in order to function properly.

These may include a variety of different semiconductor switching elements, such as photocouplers, diodes, transistors, thyristors and more.However, while technically impressive and extremely useful in a range of different scenarios, the added complexity of SSRs means that they do also have their perceived drawbacks when compared to EMRs in certain uses or environments. These might include:

• Reduced overall efficiency in terms of effective voltage transfer compared to EMRs (there will always be a fixed drop-off on the output side)

• This might make very little difference at higher voltages, as it’s fixed rather than proportional – but at lower voltages, it will be comparatively much more significant

• This can make a noticeable difference to equipment on the output side, impacting its ability to run at full power

• There is almost always some form of ‘leakage’ current when an SSR is supposedly in an open position

• This makes them unsuitable for use in many types of safety disconnect, as they can still transfer current (and deliver a shock) at high voltages even when ‘off’

• Vulnerability to being triggered by very brief voltage spikes and surges, which a less responsive EMR would typically ‘ignore’

• Greater potential for SSRs to overheat when components are crowded, or when switching large loads

• Some configurations of solid state relays may require external cooling

• Although longevity is commonly cited as a major reason to opt for SSRs over mechanical relays, many of the potential failure points in either type of relay don’t involve the moving parts themselves

• Some argue this makes the difference in perceived durability something of a ‘theoretical’ advantage, rather than a very practical one

• Solid state relays tend to considerably more expensive than mechanical ones

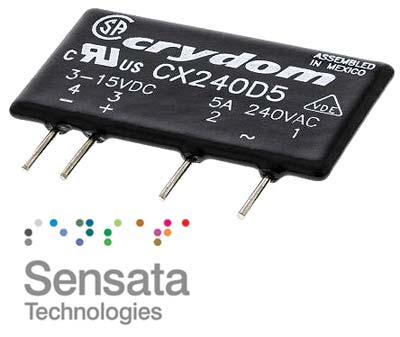

Sensata / Crydom 5A Solid State Relay, Zero Cross, PCB Mount

RS Stock # 291-2371

RS Stock # 291-2371

Mfr. Part # CX240D5

• Exceptional surge rating and steady state rating of 5Aac

• Models to switch from 48-660Vrms

• 250A pk 1-cycle surge capability

• Input-Output capacitance: 10pF

• Zero-cross switching where stated otherwise random-fire

• Operating temperature range: -30 to +80°C

• Dimensions (mm) H33 × W7.6 × D43.1

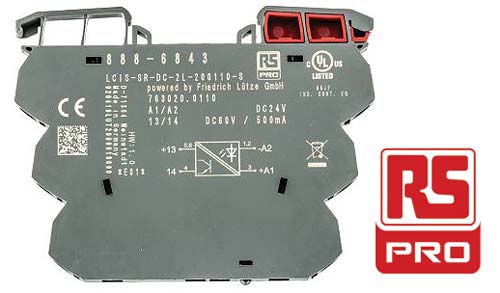

RS PRO, 0.5A SPNO Solid State Relay, DC, DIN Rail, MOSFET, 60V Maximum Load

RS PRO, 0.5A SPNO Solid State Relay, DC, DIN Rail, MOSFET, 60V Maximum Load

RS Stock # 888-6843

Interface Solid State Relays – Covering a wide range of applications offering extremely accurate processing, especially for coupling signals and for switching loads of up to 250 V/16 A at temperatures ranging from -40 to +75°C.

A compact width of 6.2mm, which is excellent for narrow applications. Also available with spring loaded connections for areas with strong vibration.

Finder, 25A SPNO Solid State Relay, Zero Crossing, Heatsink, 280Vac Maximum Load

RS Stock # 800-2934

Mfr. Part # 77.25.9.024.8250

• Finder 77 Series – 25, 40 and 50 A panel solid state relays, hockey puck style, specially designed for heater control applications.

• Finder 77 Series – 25, 40 and 50 A panel solid state relays, hockey puck style, specially designed for heater control applications.

• 48 to 600V ac output

• Zero-crossing switch-on version

• High switching speed and endurance

• Silent, spark and bounce-free switching

• Low control power

• Relay-style terminal arrangement (input and output terminals on opposite sides)

• Mounting on heatsink with screws

• IP 20 protection category

• Heat-sinks also available for models 77.25, 77.45 and 77.55

Celduc, 12A Solid State Relay, Zero Crossing, Chassis Mount, Triac

Celduc, 12A Solid State Relay, Zero Crossing, Chassis Mount, Triac

RS Stock # 499-0446

Mfr. Part # SO941460

• Synchronous solid state relay suited to most loads.

• TMS2 technology thyristor output ensures longevity.

• Voltage protection for input as well as output (VDR) for very high immunity to interference.

• Wide control range: 20 → 265 Vac/dc with regulated control current.

• Green LED input display.

• Solid state relays must be mounted on a heatsink.

Author:

Bogdan Grămescu

![]() Aurocon Compec

Aurocon Compec

https://www.compec.ro

Aurocon COMPEC distribuitor autorizat RS Components