Space is at a premium on the boards of most end devices, and so plug connectors need to be shrunk ever further. Manufacturers are already offering relevant products – and many miniaturized solutions even feature added bonuses.

Despite 2.54 mm or 5.08 mm being the ideal (pitch) dimensions for plug connectors for the longest time, even smaller pitches of as low as 0.5 mm are in demand today. They aim not only to conserve space on the board, but also generally enable greater contact density overall. The potential for pitches of 0.4 mm and 0.2 mm to be established in Europe is limited. The Far East is the more relevant target market, where such dimensions are applied to smartphones and other entertainment electronics.

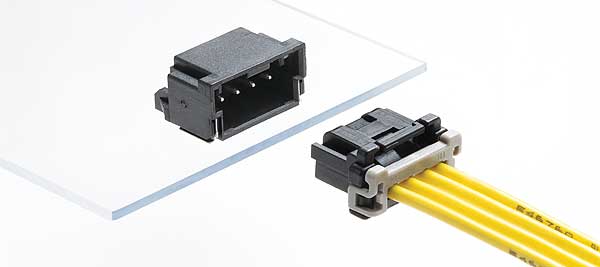

However, modern plug connectors need not only to be smaller, but also provide greater stability, performance and convenient connection mechanisms. For instance, the active latch mechanism provides a secure mechanical connection in applications where there are strong tensile forces or vibrations. Unlike other systems, active latch housings with standard headers in a single series always fit together, thereby guaranteeing 100% modularity and exchangeability within a plug connector system. The housing consists of a high-temperature plastic and can withstand operating temperatures of up to 125°C.

PRBX GB350 – “Poke-home” contacts are a low-cost and yet robust discrete wired connection solution that does not involve additional expense for the insulation or assembly. (Source: AVX)

Reliable Connections

Reliable signal communication under any operating conditions – including vibration – is particularly essential with engine control devices in automobiles, especially for safety-critical components such as the airbag and ABS/ASR. Models with TPA (Terminal Position Assurance) are supplied with a locking mechanism that prevents the contacts from accidentally becoming disconnected. When plugged in a certain position, the position assurance mechanism, which is implemented in the form of a lever, can secure the lever on the plug connector itself or a counterpart connector so that neither can be separated from the other. However, it is not absolutely necessary for the plug connector to be connected to the counterpart connector using the lever. It is also possible to use the lever on the plug connector as a “backup” in which case the locking mechanism of the connector largely handles the position assurance.

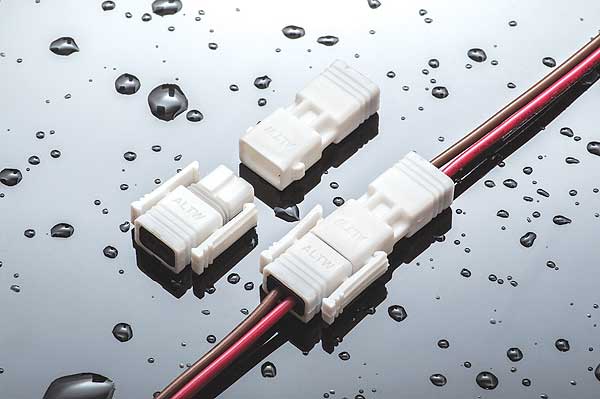

For Harsh Environments

The SSL 1.2 series from Amphenol Industrial with IP68 protection when plugged, for instance, is ideal for use in wet and dirty environments. The pre-assembled solutions provide considerable savings potential on the board and in use.

Thanks to LV214 certification, the DuraClik™ series with a pitch of 2.00 mm and the Minitek Microspace™ series from Amphenol ICC with pitches of 1.27/1.50 mm are suitable for automotive and other applications such as non-automotive transportation and industrial production machinery (factory automation) that require high resistance to vibration. The form-fit and heat-resistant design of the DuraClik™ family enable high space reductions and reliable contacts in high-vibration applications. The Minitek Microspace™ plug connectors have primary and secondary contact retention, poka-yoke polarization as well as a “visual mismatch prevention system” that eliminates the risk of improper connections. It also benefits from a compact construction and a PCB footprint that is half the size of comparable plug connectors on the market.

Less Is More

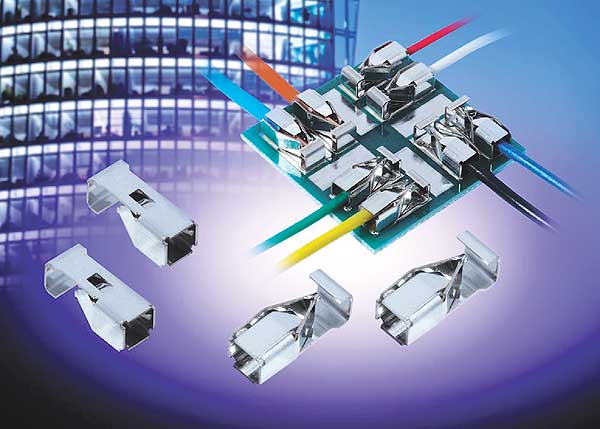

When it comes to accounting for cost, the product designer’s motto is “less is more”! For instance, they are increasingly leaving away the plastic coating for the housing. Contact protection is already becoming increasingly unnecessary, in part because the boards are installed so as to be inaccessible or are encapsulated by casting. Additionally, the plastic does not perform any locking or retention function. Also, the omission of unnecessary plastic is consistent with environmentally-consciously thinking. The patented STRIPT™ plug connectors from AVX – originally known as “naked” – are among the cheapest solutions in this segment. They require neither the space nor the assembly costs required for plastic insulation. Even so, Insulation Displacement Connector (IDC) technology enables gas-tight, castable connections with secure contacts that can also withstand vibration. They are also available with poke-home WTB technology. The individual UL-certified contacts provide the same performance as complete plug connector solutions.

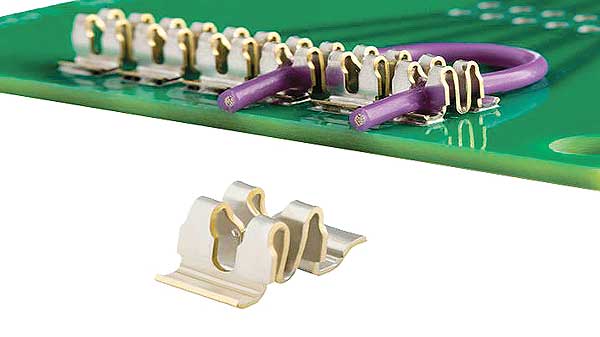

Flat, compact and low-cost – the miniature Griplet® IDC plug connectors Amphenol ICC. (Source: Amphenol ICC)

The miniature Griplet® IDC plug connectors from Amphenol ICC are a low-cost solution for wired connections. Due to its flat, compact design with a height of 3.7 mm and a surface of 4.0 mm × 6.1 mm, it is ideal for limited-space applications in harsh environments. It can hold multiple wires of 20–32 AWG. Double connection points with tension relief ensure stable operation even under extreme temperature, impact and vibration conditions. In order to respond to such needs among others, manufacturers in this price-driven market rely both on low-cost connector technologies and on high volumes through greater versatility. Distribution partners also provide some relief on the market. Both manufacturers and customers benefit from their advice, value-added services and logistical handling. Because they are also capable of serving smaller customers than the manufacturers themselves, they are also capable of catering to other market segments for the components.

Optimizing Costs during Production

Adam Tech makes it possible to optimize component costs even while production processes are underway. This manufacturer is able to replace designed-in plug connectors while ensuring compatibility – all the while maintaining maximum quality at competitive prices. In accordance with patent rights, a variety of customized reproductions are possible – alternatively, plug connectors can be created with pin compatibility. This enables any flaws in the reproduction design to be eliminated. Because these solutions are also increasingly in demand for automotive applications, Adam Tech is currently undergoing TS16949 certification.

Author: Harun Ilhan, Product Sales Manager Connectors and Cables

Rutronik | www.rutronik.com

![]()