The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, will present a trio of new thermal interface materials at Electronica 2024 (November 12-15, Munich, Germany). Exhibiting on booth B3.236, innovations on show will include new thermal cure-in-place, gap pad and dispensable gel products. Parker Chomerics is also planning a significant announcement involving the launch of a rapid sampling and prototyping service.

The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, will present a trio of new thermal interface materials at Electronica 2024 (November 12-15, Munich, Germany). Exhibiting on booth B3.236, innovations on show will include new thermal cure-in-place, gap pad and dispensable gel products. Parker Chomerics is also planning a significant announcement involving the launch of a rapid sampling and prototyping service.

With ever-evolving demands and trends in the electronics industry, Parker Chomerics strives to remain ahead of the competition by developing timely solutions to emerging challenges. The new thermal interface materials on display at Electronica 2024 maximise thermal management performance in some of the most demanding applications, overcoming key industry issues such as oil bleed, vertical tackiness and the limitations of hard-curing dispensables.

Thermal interface materials transfer heat away from electronic components and other heat-generating devices. They also perform gap-filling duties in certain applications. A case in point is the new THERM-A-FORM™ CIP 60 cure-in-place material and thermal gap filler. With its high 6.0 W/m-K thermal conductivity, the new product not only provides an appealing alternative to hard-curing dispensable materials in electronics cooling applications, it also offers an improvement over standard application methods associated with thermal gap filler pads.

Visitors to the booth will discover that this two-component material can deliver an exceptional flow rate and meet high-volume dispensing requirements. E-mobility systems, automotive infotainment, automotive ADAS (advanced driver assistance systems), and consumer and enterprise SSDs (solid-state drives) can all benefit from THERM-A-FORM™ CIP 60.

Parker Chomerics will also exhibit its new THERM-A-GAP™ 80LO high-performance thermal gap pad with very low oil bleed and migration characteristics. Ideal where the aesthetic or manufacturing issues of silicone oils are an issue, the new gap pad offers a typical thermal conductivity of 8.0 W/m-K. A compressible thermal elastomer, THERM-A-GAP™ PAD 80LO conducts heat in gaps between a heat-generating surface like a semiconductor or battery and a heat-dissipating surface.

THERM-A-GAP™ 80LO minimises stress on components like integrated circuits and also provides physical protection such as vibration damping. Applications include GPUs, CPUs and memory modules, as well as 5G and telecommunications equipment. Automotive sensors and devices, battery and energy storage modules, and defence electronics can also benefit.

Another new product highlight at Electronica 2024 will be THERM-GAP™ GEL 75VT, a high-performance dispensable thermal gel offering 7.5 W/m-K typical thermal conductivity and vertical tackiness for use in demanding and mission-critical applications. In long-term reliability tests, the new material passed automotive vertical slump testing, high-vibration tests and telecommunications thermal material verification processes.

The single-component THERM-GAP™ GEL 75VT is suitable for use in automotive sensors and devices, telecommunications modules, BESS (battery and energy storage system) modules, industrial electronics, network and IT infrastructure, power electronics, and consumer electronics. Users can dispense the thermal gel at bond line thicknesses up to 4 mm.

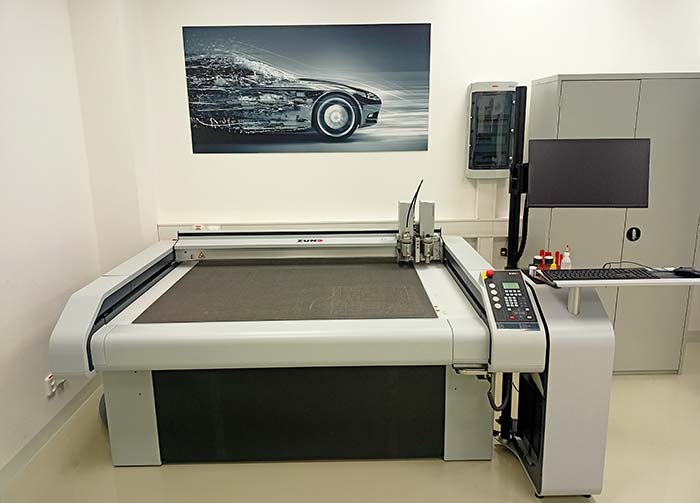

Parker Chomerics will also showcase its new rapid sampling and prototyping facility located in the Czech Republic. Representing significant capital investment, the new facility offers customers access to state-of-the-art machinery for delivering high-quality standard and custom samples in very short lead times.

Please speak to one of the team’s friendly and professional experts on the booth for more information about the new service or any of the thermal interface materials or EMI shielding solutions available from Parker Chomerics.

Chomerics

PARKER HANNIFIN CORPORATION