The assembly and connection technology using enamelled copper wire technology is a core process, especially for future mobility requirements. More and more regenerative energy generation systems are being installed in electric drive of modern vehicles, for which electric generators must be integrated. In addition, today’s e-mobility concepts require a large number of switching and transformation components, coil bodies, magnetic heads, sensors, relays and other exotic electronic components, for which enamelled copper wire technology is also used in production.

The assembly and connection technology using enamelled copper wire technology is a core process, especially for future mobility requirements. More and more regenerative energy generation systems are being installed in electric drive of modern vehicles, for which electric generators must be integrated. In addition, today’s e-mobility concepts require a large number of switching and transformation components, coil bodies, magnetic heads, sensors, relays and other exotic electronic components, for which enamelled copper wire technology is also used in production.

For these many new requirements, enamelled wire manufacturers are constantly developing new products, which are equipped with a wide variety of insulation materials, some of which are also newly developed. This is intended to improve the insulation class and thermal resistance for future end products. “This development always presents us with challenges,” says Matthias Fehrenbach, Managing Director of Eutect GmbH. Because, by using the usual soldering techniques under normal atmosphere, it is impossible to process components coated with polyurethane or polyesterimide in such a way that no oxide formation occurs, or insulation residues considerably reduce the final soldering quality of the tinned wire.

For these many new requirements, enamelled wire manufacturers are constantly developing new products, which are equipped with a wide variety of insulation materials, some of which are also newly developed. This is intended to improve the insulation class and thermal resistance for future end products. “This development always presents us with challenges,” says Matthias Fehrenbach, Managing Director of Eutect GmbH. Because, by using the usual soldering techniques under normal atmosphere, it is impossible to process components coated with polyurethane or polyesterimide in such a way that no oxide formation occurs, or insulation residues considerably reduce the final soldering quality of the tinned wire.

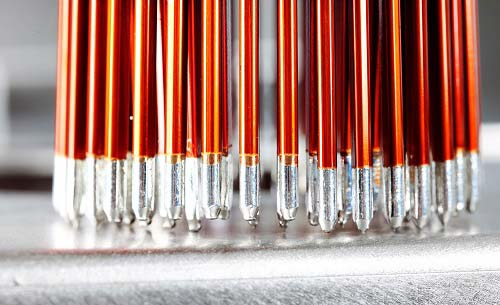

In its module toolbox, Eutect has all selective soldering methods at its disposal that are capable of thermally stripping coated enamelled copper wires in one step without additional removal of the insulation. Lead-free processing with all its specific process finesses with regard to the specific solder alloy, the flux, the temperature-time curve with flowing or standing solder melt is the comprehensive core know-how of a target-oriented process processing. High-temperature soldering systems from Eutect have been developed for this purpose. These systems work with the static or flowing solder melt.

In its module toolbox, Eutect has all selective soldering methods at its disposal that are capable of thermally stripping coated enamelled copper wires in one step without additional removal of the insulation. Lead-free processing with all its specific process finesses with regard to the specific solder alloy, the flux, the temperature-time curve with flowing or standing solder melt is the comprehensive core know-how of a target-oriented process processing. High-temperature soldering systems from Eutect have been developed for this purpose. These systems work with the static or flowing solder melt.

It is important to achieve a high quality of copper alloying, leaching and soldering. By using the static or flowing solder melt as well as an exact temperature-time curve, the process-conserving and product-specific stripping is defined. In order to counteract various negative effects, newly developed or yet to be developed solders with doping properties are used. These reduce wire deposition, solder oxide formation and solder contamination and protect the soldering equipment.

The high-temperature process for tinning from Eutect can be carried out with a static solder bath and a dynamic, freely programmable squeegee system. This reduces contamination and keeps the base alloy of the solder constant. Thus, the alloy remains in its original composition throughout the entire process. The controlled removal of the contaminated solder and the automatic solder replenishment of the base solder are thus kept constant over the entire production quantity. For a clean delineation of the lacquer between the tinned wire and the poly insulation, the wire ends can be kinematically moved during the immersion movement in the static or flowing solder wave or can be cleanly delineated with appropriate masking. This prevents burn-off residues of the poly insulation from sticking to the bare tinned and stripped wire or from visibly sticking to the wire as black dots, thus reducing quality. Although these impurities are harmless, they do not look nice.

Surfaces that come into contact with the hot solder are completely protected by special coatings, both in the static or flowing solder melt. In addition, an induction solder pump, which is free of moving parts, was developed for this area of application. The specially programmed algorithms with associated process control, redundant monitoring of the solder melting temperature as well as a nitrogen protective gas bell above the solder process surface and the height control of the solder waves round off the high-temperature soldering system. This includes an input HMI and process data acquisition for process tracking.