Farnell element14, the Development Distributor, has expanded its portfolio of inertial sensing solutions with the full range of high-performance MEMS gyros from Tronics Microsystems, a division of TDK Corporation that manufactures standard inertial sensors and custom MEMS products. This expansion strengthens Farnell element14’s offering for customers looking for innovation, advanced technologies and high performance solutions.

Farnell element14, the Development Distributor, has expanded its portfolio of inertial sensing solutions with the full range of high-performance MEMS gyros from Tronics Microsystems, a division of TDK Corporation that manufactures standard inertial sensors and custom MEMS products. This expansion strengthens Farnell element14’s offering for customers looking for innovation, advanced technologies and high performance solutions.

“Tronics’ GYPRO® closed-loop MEMS gyros take MEMS inertial sensors to an unrivalled level of performance with excellent measuring accuracy and long-term stability”, says Andrea Riverso, Head of Product Management, Semiconductors at Premier Farnell and Farnell element14: “This collaboration with Tronics strengthens our portfolio by addressing new customers and applications on the high-end side of the motion sensing sector, and we are looking forward to adding further new products from Tronics in the future.”

“We are delighted to have our high performance MEMS gyros now part of Farnell element14’s portfolio of inertial sensing solutions. Partnering with such a key distributor will strengthen the exposure of our standard inertial products as well as our recognized expertise in this field”, said Vincent Gaff, Tronics’ Director Marketing and Business Development. “This move will further structure our supply chain at global level thanks to Farnell element14’s reliable and responsive distribution capabilities, and will open up new opportunities for worldwide customers eager to integrate our current and future generation of high performance standard inertial products into their targeted applications.”

“We are delighted to have our high performance MEMS gyros now part of Farnell element14’s portfolio of inertial sensing solutions. Partnering with such a key distributor will strengthen the exposure of our standard inertial products as well as our recognized expertise in this field”, said Vincent Gaff, Tronics’ Director Marketing and Business Development. “This move will further structure our supply chain at global level thanks to Farnell element14’s reliable and responsive distribution capabilities, and will open up new opportunities for worldwide customers eager to integrate our current and future generation of high performance standard inertial products into their targeted applications.”

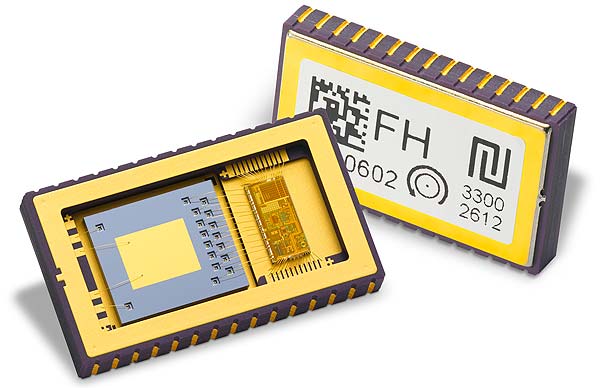

Tronics high performance MEMS inertial sensors are ideally suited for system manufacturers with strong requirements for high bias stability and high-performance inertial sensors. Key applications include precision navigation, motion tracking and control, and optical stabilisation. Tronics’ comprehensive sensor portfolio brings a tailored solution to support system manufacturer’s transition to MEMS products, with huge benefits in terms of size, weight, power and price, without compromising on performance and reliability.

The Tronics’ GYPRO® series combines several key benefits on a single chip, and features bias instability of only 0.8̊ per hour and ultra-low noise (Angular Random Walk) of only 0.14° per √h. The standard GYPRO2300 product features a data rate of 200 Hz with RMS Noise [1-100Hz] of 0.02°/s; the GYPRO2300LD offers a data rate of 1700 Hz at 2ms latency tailored for motion tracking and stabilisation. The GYPRO3300 boasts improved tolerance to harsh environments (vibration rectification coefficient of 0.5°/h/g²) and a latency of 1ms due to improved integrated circuitry, tailored for precision navigation and stabilisation.

The built-in closed-loop electronics brings several key advantages, including superior linearity, increased signal to noise ratio and improved behaviour in harsh vibration, shock and temperature environments.

Tronics standard products are manufactured at the company’s Crolles facility near Grenoble, France, and calibrated over a broad temperature range, allowing for high-accuracy digital output.

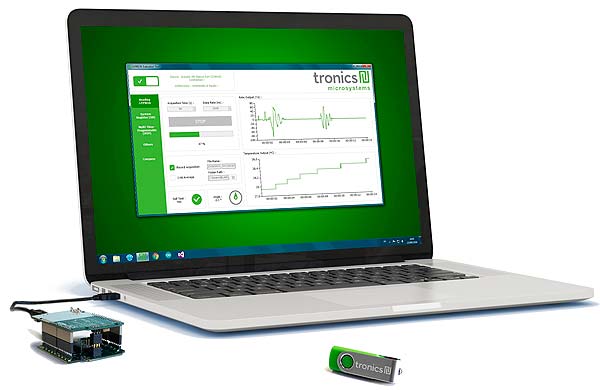

In addition to the portfolio of high performance MEMS standalone gyros available for same day shipping, Farnell element14 also stocks Tronics GYPRO®-EVB2 evaluation kits which are specifically designed to interface with the Arduino YUN open-source electronic prototyping platform. These plug-and-play system feature a compact design and integrate the Tronics proprietary evaluation software to help design engineers test and develop Tronics standard high-performance MEMS gyros into their own designs.

Farnell element14 | http://farnell.com