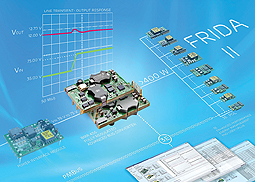

Ericsson has unveiled its second digital-power Advanced Bus Converter platform for use with board-mounted DC/DC power modules in telecom and datacom applications. The company’s new FRIDA II platform integrates an unprecedented number of technical innovations and industry firsts to make a significant contribution in further reducing energy consumption. Delivering lower power dissipation in end-customer systems – decreasing the requirement for hard cooling – the new platform will also bring higher reliability, lower CO2 emissions and lower Total Cost Of Ownership (TCO2). Ericsson was the first company to introduce digitally controlled and PMBus-compliant advanced DC/DC bus conversion technology with its BMR453.

Patrick Le Fèvre, Marketing and Communication Director of Ericsson Power Modules said: “Ericsson has a strong track record in delivering leading-edge DC/DC advanced bus converter technology to the market. In 2008, Ericsson pioneered breakthrough technology in the introduction of digitally controlled DC/DC Advanced Bus Converters. Now, in this major step forward in the company’s continuous quest to deliver energy-optimized solutions, the FRIDA II platform will further enable its customers to reduce their energy consumption and carbon footprint.”

High Efficiency Across the Range

Built around the capabilities of the 32-bit ARM7TDMI-S microprocessor core, the FRIDA II platform integrates brand new hardware and firmware that has been optimized to guarantee the highest efficiency at any point of operation. The platform offers a tightly regulated output voltage (2%) across the entire operational range – from 36V to 75V – together with an unprecedented output response to input disturbances such as line transients.

FRIDA II also includes proprietary firmware developed by Ericsson to integrate complex scenarios and the challenges faced by DC/DC board-mounted power supplies in telecom and datacom applications, such as in Advanced Telecommunications Computing Architecture (ATCA or AdvancedTCA) or remote telecom equipment that is connected to an unstable power grid.

Ultra-Fast Algorithms and Enhanced Hardware Deliver High-End Performance Exploiting the possibilities offered by its core processor’s fast response and computational abilities, the embedded firmware integrates an ultra-fast response-loop algorithm. The algorithm adjusts parameters to guarantee output voltage will always be contained within a narrow band-gap, and remain tightly controlled whatever the input conditions, over the input voltage range from a low 36V to a high 75V.

Ericsson’s proprietary dead-time control algorithm has also been augmented with additional functionalities to reduce switching power losses and ease component stress during switching, even further increasing the outstanding reliability of the original FRIDA I platform. This combined with a unique integrated transformer layout and the use of leading-edge power transistor technologies enables the FRIDA II platform to deliver the high level of performance required in Information and Communication Technology (ICT) applications.

High Reliability and Isolation

Compared to the FRIDA I platform, the implementation of a highly advanced power controller, in conjunction with control algorithms, has made it possible to reduce the number of components used in the FRIDA II platform by approximately 10%. This contributes to a reduction in cost and a further increase in reliability. The platform’s integrated transformer and feedback components have also been specially designed to meet 2250 VDC isolation requirements for applications requiring this high level.

FRIDA II – The First Products

The first product based on the FRIDA II platform will be a quarter-brick advanced bus converter, called the BMR456, which will deliver an output power of 400W and above; followed by a new eighth-brick format device, the BMR457, which will deliver an output power of 250W and above.

The FRIDA II platform is part of the Ericsson 3E* products and patents portfolio. Through close cooperation with board and systems designers, the company was the first to release a 21st century power architecture that can be fully integrated into the rest of the digital chain of processors and associated components.

* Enhanced Performance, Energy Management, and End-user Value are the key benefits delivered by Ericsson’s range of 3E digitally controlled DC/DC converters.

Ericsson Power Modules

www.ericsson.com/powermodules