Myself and the other founders of ALL Circuits, started our adventure together with a very clear mission – to save the 400 jobs at the former Valeo, then Jabil factory in Meung sur-Loire just south of Paris. The facility had been inaugurated by Valeo in 1992 and acquired by Jabil ten years later. By 2009 it was clear the factory had to be sold or it would close. So along with Isabelle Homo, Fabrice Menard and Gérard Leplanquais, we set about finding a way to keep the facility and the jobs of the 400 or so employees alive. That’s when ALL Circuits, initially called MSL Circuits was born.

Myself and the other founders of ALL Circuits, started our adventure together with a very clear mission – to save the 400 jobs at the former Valeo, then Jabil factory in Meung sur-Loire just south of Paris. The facility had been inaugurated by Valeo in 1992 and acquired by Jabil ten years later. By 2009 it was clear the factory had to be sold or it would close. So along with Isabelle Homo, Fabrice Menard and Gérard Leplanquais, we set about finding a way to keep the facility and the jobs of the 400 or so employees alive. That’s when ALL Circuits, initially called MSL Circuits was born.

By Bruno Racault, President, ALL Circuits

Survive and Thrive

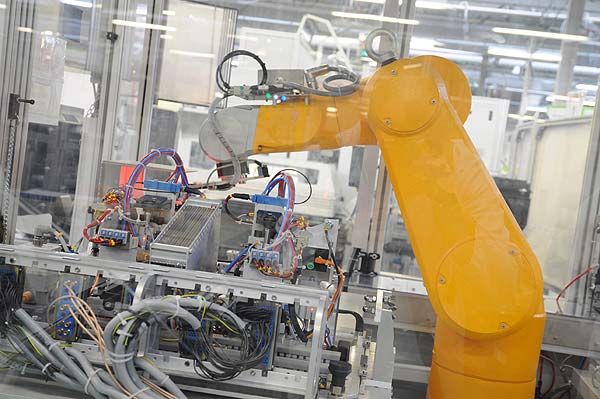

Whilst our initial objective was survival, we knew our future could only be secured if we adapted to become a more automated, efficient business. Our second goal was to put operational excellence and automation at the core of our ideology. As the management buyout team was largely populated with operational experience this seemed a natural focus for us.

In many ways, we were bucking a trend at the time. Manufacturing jobs were leaving western Europe at an alarming pace, headed for Asia and for lower cost countries is eastern Europe. But we believed that if we could maintain exceptionally high standards of quality, performance and customer service, combined with labor costs kept below 5% of the product cost we could still compete. We were right, and between 2010 and 2017 our revenues grew from 88 to 214 million euros. Our initial goal was met, the 400 jobs was safe and the facility that looked like closing was actually thriving.

Shortly into our journey, in 2012, we had the opportunity to grow our team and our footprint when we acquired the EMS facilities of SAGEMCOM in Bayonne, France and Tunisia, adding more capacity and of course our own lower cost manufacturing location for those projects where labor cannot be reduced with automation.

Shortly into our journey, in 2012, we had the opportunity to grow our team and our footprint when we acquired the EMS facilities of SAGEMCOM in Bayonne, France and Tunisia, adding more capacity and of course our own lower cost manufacturing location for those projects where labor cannot be reduced with automation.

It is exciting to see what can be done with these factories and how we can remain string in France through investment and development in automation. We never called it Industry 4.0, or the lights out factory, but it’s impressive when you walk the factory floor and realize that most of the team are maintaining and configuring the lines, developing new processes and ensuring materials are ready and available. Very few are touching the product or undertaking any manual assembly process.

The Next Chapter

Our next era of growth will be developing beyond the confines of the normal manufacturing process and beyond our current geography. Both developments have come about because we listen to our customers constantly and invest to serve their plans as much as our own.

Our next era of growth will be developing beyond the confines of the normal manufacturing process and beyond our current geography. Both developments have come about because we listen to our customers constantly and invest to serve their plans as much as our own.

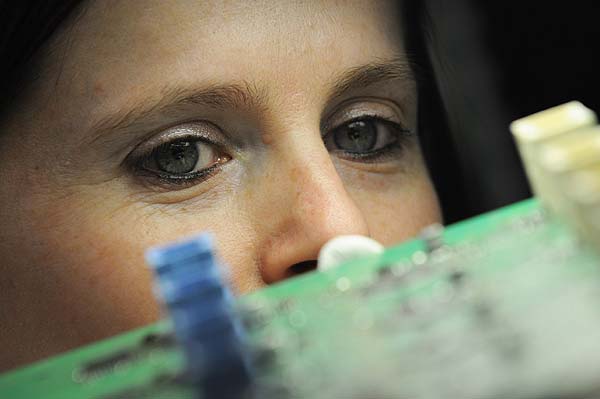

Recently ALL Circuits acquired a design company in Angers, not too far from Meung sur-Loire. We recognize that many brands want a design element available to them as well as manufacturing. Creating a seamless link between the innovation process and manufacturing is a great way of ensuring a design can be made and delivered at scale and globally. We also recognize that some companies are moving into technology for the first time and our design expertise and experience is essential to helping them create the smartest solution.

Recently ALL Circuits acquired a design company in Angers, not too far from Meung sur-Loire. We recognize that many brands want a design element available to them as well as manufacturing. Creating a seamless link between the innovation process and manufacturing is a great way of ensuring a design can be made and delivered at scale and globally. We also recognize that some companies are moving into technology for the first time and our design expertise and experience is essential to helping them create the smartest solution.

Our other major development has been our entry into the Americas, through a brand-new plant in Guadalajara. This is a child in the image of its parent, with identical lines to those in our largest facility in Meung sur-Loire. It is informed by everything we’ve learned over our 25 years in automotive electronics and will serve both new and existing customers wanting ALL Circuits’ exceptional quality and value delivered locally into the Americas and, in particular, the USA.

The circumstances that set us on our adventure nearly ten years ago has informed our progress and will inform our future. ALL Circuits is determined to be global EMS provider, maintaining high standards for automation, quality, performance and value everywhere. Our staff, starting with those 400 in Meung sur-Loire, but now close to 2,000 worldwide, remain at the core of our DNA. They are ALL Circuits.