As the demand for high performance electronics increases globally, Altus Group, a leading supplier of capital equipment in the UK and Ireland, is helping manufactures to find low-void soldering solutions thanks to its latest equipment including vacuum systems from Rehm Thermal Systems.

As the demand for high performance electronics increases globally, Altus Group, a leading supplier of capital equipment in the UK and Ireland, is helping manufactures to find low-void soldering solutions thanks to its latest equipment including vacuum systems from Rehm Thermal Systems.

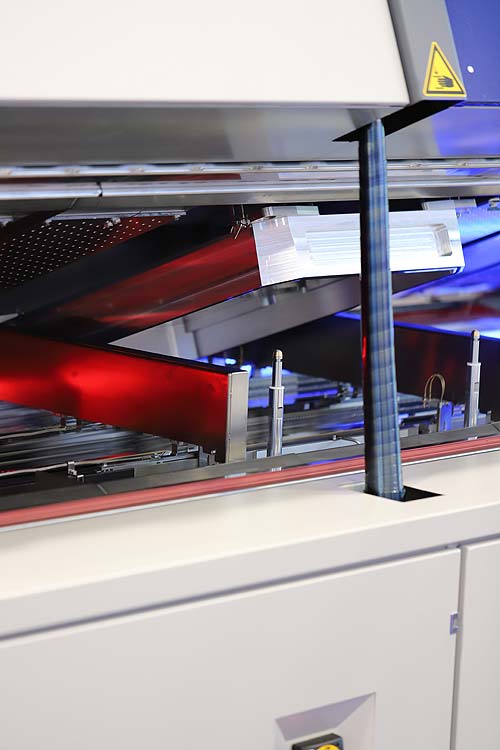

Altus is continually adding and updating equipment to its portfolio which offers sustainable solutions for the increasing demand for complex electronics. Rehm’s VisionXP+ Vac convection soldering system is one of the machines helping in this effort. It offers a flexible 2-in-1 solution for reflow soldering. Matthew Jones, Altus Sales Director explains: “As electronics becomes more intricate it is important to achieve solder joints with fewer voids.

“To reliably produce solder joints with very few voids, soldering systems with vacuum chambers are essential for removing the gases from the molten solder joint once the solder paste has been remelted. Rehm’s VisionXP+ Vac convection soldering system offers an energy-efficient solution with a flexible vacuum option.

“We have seen substantial interest in the system since its introduction and its significance in providing the very best solutions for today’s modern electronics is being recognised.”

The VisionXP+ convection soldering system with vacuum option removes voids while the solder is still in its optimal molten state. With a vacuum under 100 mbar, void areas of less than 2 percent can be achieved. Soldering with vacuum is particularly suitable for dissipating heat in demanding assemblies or for assemblies for power electronics. The number of voids are minimised by the vacuum, therefore achieving a better electrical and thermal connection. Integrated pyrolysis and separate filtration of the extracted atmosphere in the vacuum chamber are further advantages for maintaining and cleaning the system.