As the interface between humans and machines, the importance of the display has risen sharply due to the rapid and steady development of microelectronics. Today, every scrap of data recorded in our daily lives is visualized: the display of personal performances, requests in the consumer, medical, and POS sector, along with measurements, check and optimization values in the industrial and automotive sector, as well as simple status displays for smart homes or metering. This has definitely extended the field of application for displays considerably.

As the interface between humans and machines, the importance of the display has risen sharply due to the rapid and steady development of microelectronics. Today, every scrap of data recorded in our daily lives is visualized: the display of personal performances, requests in the consumer, medical, and POS sector, along with measurements, check and optimization values in the industrial and automotive sector, as well as simple status displays for smart homes or metering. This has definitely extended the field of application for displays considerably.

And each application requires a different display. A thermostat display mounted on the wall of a room can be viewed from all angles, while the head-up display inside a car can only be seen by the driver and not the passenger. Some displays have stronger background lighting, others have none at all and operate in a purely reflective mode. The list of examples for the varying properties of individual displays could go on and on.

Passive and active displays

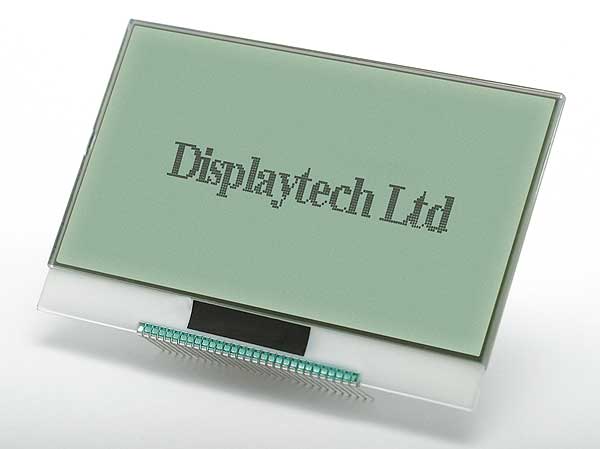

Large strides have been made in the area of image presentation technologies in recent decades. A special role in this respect is attributed to passive displays, since they have always been a model of individualism due to their simple control, reduced depth of installation, and technological diversity. Customized passive LCD displays were, and still are, a popular choice for numerous applications, from pocket calculators and simple measuring devices, such as gas and water meters, to smartwatches, temperature displays, home appliances, and industrial measuring instruments. In contrast to active TFT displays, the tooling costs and MOQs for a full custom solution are much lower for passive LCD displays and easier to implement for smaller projects and companies. The tooling for a fully customized TFT may cost roughly US$200,000, which often exceeds the allocated budget. On the other hand, a passive display can be tooled as a reflective display module for about US$2,000 and, depending on its technology and complexity, as a passive display module for between US$2,000 and US$5,000.

Another argument in favor of a customer-specific LCD display is its long-term availability. While the availability of standard modules in the TFT sector is limited to between three and five years, a custom LCD can, theoretically, remain in production as long as the owner of the tooling tool wants to manufacture the display. Projects lasting five, ten or fifteen years are thus not out of the question.

Contrast and temperature application range

Contrast and temperature application range

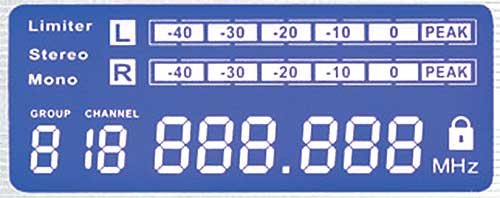

The passive LCD is, however, not usually top of the list when planning the application’s visualization. This is basically down to the significance which society and marketing ascribe to a smartphone or tablet: The display must light up and show values in vivid colors, while it must be possible to switch and zoom in on different touch screen content. But a passive LCD also offers advantages and does not just consist of a simple 7-segment display, well established in pocket calculators and which flourished in the yellow/green STN cell of the Nintendo Game Boy back in the 1990s.

The world of monochrome displays draws on a wide breadth and depth of technological capabilities. Vertical alignment technology, for instance, enables a super black background and an impressive 1000:1 contrast ratio, which offer crisp, clear images and space for individual design options. This technology is ideal for applications that demand wide temperature ranges and excellent clarity of viewing from every angle.

Using an ASTN-based cell, visualization technologies in the automotive or metering sector can be developed for temperature ranges from -30 to +80°C, something that would be very difficult to achieve with a TFT display. These technologies then enable both segment and graphic modules. If traditional TN, STN or FSTN technology is required for an application, the display can be tailored accordingly and the visualization used to create a unique selling proposition to make it stand out in the market.

Designing a customized display

Designing a customized display

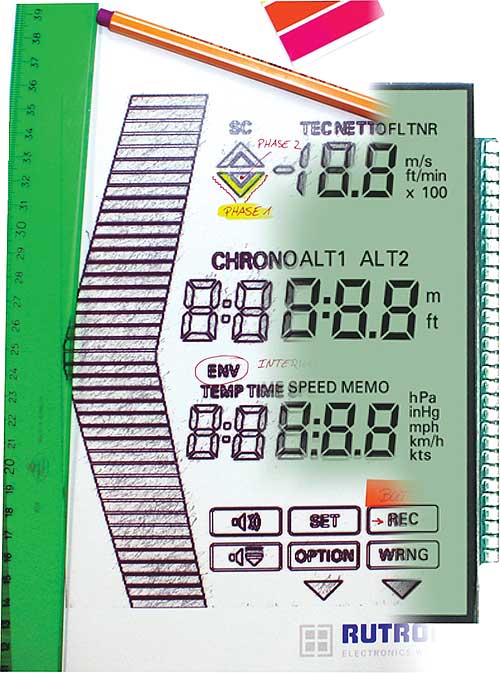

Implementation of a customized passive display is quite simple and explained in just a few steps: The visualization is the first thing to consider – what should the display look like, what size does it have to be, and which temperature range needs covering? In addition, is background lighting or a specific viewing angle desired, and should it contain graphical image points or even predefined segments? It is also important to define which technology is appropriate for the application.

To answer all these questions correctly, the Rutronik Embedded Display team offers pinpoint advice and helps pick the right supplier for the respective application. The team supports customers from the first sketch and approved samples for the prepared specification through to mass production in cooperation with the suppliers.

Once every question has been answered and, if necessary, a layout or sketch has been completed for implementation, renowned suppliers of passive LCDs, such as Yeebo Display, Tianma Micro or U.R.T., prepare a detailed drawing of the desired display within one working week. This usually occurs after agreeing the tooling costs with the supplier. Production of the approved samples occurs as soon as the drawing has been released, between five and ten displays are included in the tooling costs. Depending on the level of complexity, these can take five to eight weeks to produce for reflective displays and ten to fourteen weeks for display modules. Based on the released displays, the supplier prepares a detailed specification which in turn is checked and approved along with the samples. Then it is time for serial production, and after approximately ten to fourteen weeks, full scale production can begin.

The Embedded Display department ensures Rutronik is set up perfectly for comprehensive project management. During the start-up phase, communication with the supplier is carried out 100% by the Product Marketing team, which also coordinates all the relevant activities. Working hand in hand with the customer as part of the aftersales service offered, the distributor ensures a successful display tailored to the individual application.

Autor: Vincenzo Santoro, Senior Marketing Manager Displays & Monitors

Rutronik | www.rutronik.com

![]()

Rutronik | www.rutronik.com