Why it’s time to re-think your approach to Maintenance?

Unplanned maintenance and the resulting production downtime are the bane of most organizations. Deloitte reports that such downtime costs industrial manufacturers £37 billion [$50 billion], and that 42% downtime is caused by equipment failure.

Unplanned maintenance and the resulting production downtime are the bane of most organizations. Deloitte reports that such downtime costs industrial manufacturers £37 billion [$50 billion], and that 42% downtime is caused by equipment failure.

The combination of connected technology (the Industrial Internet of Things) becoming available at lower costs and greater data analytics makes it possible to monitor almost any machine and predict failure before it happens. This makes it possible for organizations to identify problems and plan downtime to suit their own schedule.

However, access to a range of sensors is only part of the overall picture. “Intelligent maintenance is more than just technology and products, it’s actually a way of thinking,” says Richard Jeffers, Technical Director Northern Europe at RS. “It’s about anticipating potential failure and taking the right action to prevent or reduce the impact of that failure on your operations. Technology is what you use to enable and make predicting failure easier.”

The first step for organizations looking to reduce their unplanned maintenance, according to Jeffers, is to recognize the value of a predictive approach. Deloitte has found that predictive maintenance can “reduce the time required to plan maintenance by 20% to 50%, increase equipment uptime and availability by 10% to 20%, and reduce overall maintenance costs by 5% to 10%”. For many organizations, and their maintenance teams, the big question around smarter maintenance is where to start. For a lot of businesses, the test and learn approach works best as individuals and the organization as a whole establish the best solutions for their needs.

“I visited a customer’s logistics site recently and they have taken a very sensible approach to introducing maintenance intelligence into the business,” recalls Jeffers. “They had around 800 motors in their building but had identified 13 that were crucial to their operations, so they have put temperature and vibration sensors on those motors to alert the maintenance team if they start to fail. This is a trial, but the business will start to roll out the technology to other motors over the next year as the technology proves itself.”

For many organizations, there is a need for expert help and access to knowledge that will help them adopt new technology. Recent research by RS and the Chartered Institute of Procurement and Supply showed that 54% of procurement and supply professionals in the maintenance, repair and operations function want access to knowledge services from suppliers, not just the products.

“RS provides a range of sensors for customers looking to adopt and enable their smart maintenance strategy,” says Jeffers. “But we also have expertise within the business to help customers understand and make the most of IIoT. We are using this technology in our own warehouse in Nuneaton, so we have first-hand knowledge of the technology in practice.”

20mm Fuse Kit − 180 fuses

20mm Fuse Kit − 180 fuses

• A kit of 20 × 5mm fuses in both LBC and HBC formats from 0.5A to 10A – including quick blow and anti-surge versions.

• Compartmentalized storage box contains 10 of each fuse rating – ideal for service or project workshops

RS Stock No. Description

420-268 General purpose 20mm fuse kit

Meterscope

• Professional true RMS industrial digital multimeter with oscilloscope functions

• Large 50,000 count 320 × 240 TFT color LCD display

• Large 50,000 count 320 × 240 TFT color LCD display

• 20MHz/50MS/s bandwidth/Real time sample rate

• Logging function with Trend Capture for easy review of logged data

• Bluetooth PC interface for easy data transfer & accuracy calibration

• IP67 rated

• EN61010-1 CAT IV 600V, CAT III 1000V

RS Stock No. Description

144-5337 HS-608

Ferrule Crimp Kit

• A handy kit of insulated bootlace ferrules and crimp tool covering sizes of 0.5 mm² to 10 mm²

• A handy kit of insulated bootlace ferrules and crimp tool covering sizes of 0.5 mm² to 10 mm²

• 200 ferrules (0.5 − 15.mm²), 100 of 2.5mm², 50 of 4mm², 30 of 6mm² and 20 of 10mm²

• Colors follow the French color-coding standard

RS Stock No. Description

228-0321 Kit 1 contains only bootlace ferrules

266-0288 Kit 2 contains insulated bootlace ferrules and crimp tool

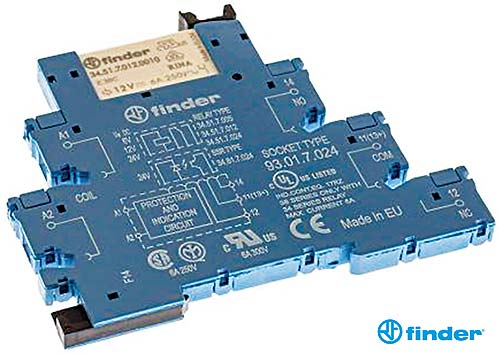

Interface Relay Modules

• Relay interface modules of 6.2mm width for use with PLC systems

• Supplied with integral coil indication and protection circuit

• Supplied with integral coil indication and protection circuit

• Easy removal of relay from module – replacement relays via Finder 34 series

• 35mm Din rail (EN 50022) mounting

RS Stock No. Description

386-4403 SPDT, 6A 12Vdc, 38.51.7.012.0050

386-4419 SPDT, 6A 24Vdc, 38.51.7.024.0050

386-4425 SPDT, 6A 24Vac/dc, 38.51.0.024.0060

431-7447 SPDT, 6A 125Vac/dc, 38.51.0.125.0060

386-4431 SPDT, 6A 230Vac, 38.51.0.240.0060

Metal Cased EN50047 Limit Switches

• GLC series die cast metal cased limit switches with IP66 protection

• GLC series die cast metal cased limit switches with IP66 protection

• 1NO + 1NC (SPDT) snap action actions rated at 10A resistive (3Aac-15)

• PG 13.5 gland entry

RS Stock No. Description

308-1793 Pin Plunger − GLCB01B

308-1816 Roller Plunger − GLCB01C

308-1822 Fixed Side Roller Lever − GLCB01A1A

308-1664 Adjustable Side Roller Lever − GLCB01A2A

308-1850 Fixed Top Roller Lever − GLCB01D

308-1670 Large Side Rotary Lever − GLCB01A9A

308-1838 Coil Spring Actuator − GLCB01E7B

308-1844 Adjustable Side Rotary Rod Lever − GLCB01A4J

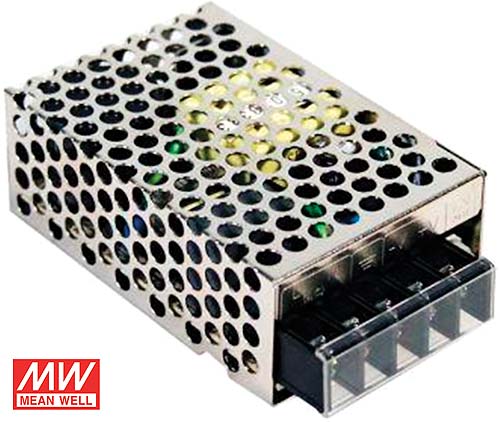

Chassis Mount Power Supplies

• Compact, high efficiency, long life switch mode power supplies with short circuit protection

• Compact, high efficiency, long life switch mode power supplies with short circuit protection

• High operating temperature up to 70°C

• Adjustable output voltage 10.8 − 13.2V at 12V

• Harmonic current compliance to EN 61000-3-2 and EMC meets EN 55022 Class B

RS Stock No. Description

621-0578 12Vdc 25W − RS-25-12

621-0590 12Vdc 36W − RS-35-12

621-0629 12Vdc 50.4W − RS-50-12

621-0635 12Vdc 72W − RS-75-12

Megger MIT500 Series Industrial Insulation Testers − 5 and 10kV

Robust and reliable testers for high performance in the real-world. The new MIT series: MIT515, MIT525, MIT1025 are designed for industrial and power distribution applications.

Robust and reliable testers for high performance in the real-world. The new MIT series: MIT515, MIT525, MIT1025 are designed for industrial and power distribution applications.

• 10 TΩ (5 kV) / 20 TΩ (10 kV) max. insulation resistance

• Timed IR plus PI and DAR diagnostic tests

• Operate with dead battery when on line power/mains

• Rapid charge Li-ion battery – up to 6 hrs continuous testing (5 kV)

• Dedicated voltmeter function (30 V to 660 V)

• CATIV 600 V safety rating

• Large LCD display with automatic backlight

• Noise filter – rejects up to 3 mA noise

• High altitude operation up to 3000 m

RS Stock No. Description

763-9260 MIT1025, Insulation Tester 20TΩ CAT IV

763-9267 MIT515, Insulation Tester 10TΩ CAT IV

6 Lock Lockout Kit

• Designed to ensure the safe isolation of an electrical circuit and prevent the supply being inadvertently turned on

• Designed to ensure the safe isolation of an electrical circuit and prevent the supply being inadvertently turned on

• Ensures the safety of workers when cleaning, servicing or repairing electrical equipment

• Kit is compatible with most circuit breakers and includes a padlock with its own unique key

• Also includes a safety hasp that enables multiple workers to lock off

• Full details are available on the RS website

RS Stock No. Description

757-5084 LOKKIT1

Author: Bogdan Grămescu

Aurocon COMPEC authorised distributor for RS Components